OriginaLast FireHalt System

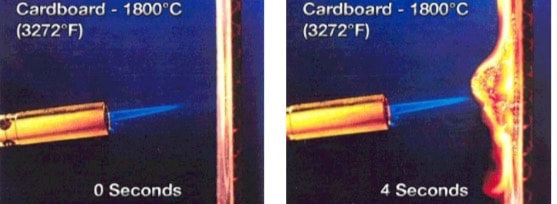

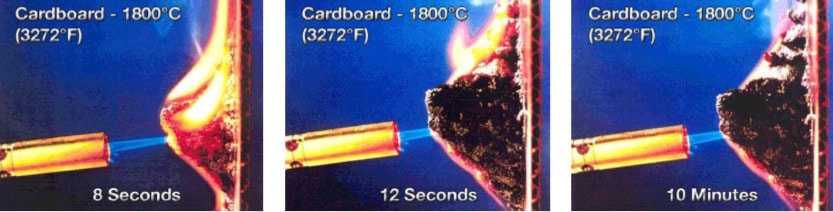

FireHalt is the name of an advanced intumescent (a substance that swells as a result of heat exposure, thus increasing in volume and decreasing in density...used for fire protection) technology.

FireHalt has roots in the fire retardant technology from the Apollo spaceship.

While not the only intumescent fire retardant technology on the market, FireHalt is by far the most economical, achieving and exceeding with small quantities the performance of more expensive alternatives.

OriginaLast is honored to be given this opportunity to introduce our state-of-the-art intumescent fire retardant technology for your consideration.

As a manufacturer of high tech products for maintaining and protecting human safety, we are confident that you will find our products and technologies to be a valuable asset to your current and upcoming projects.

OriginaLast's product line includes the following:

1. OriginaLast "Original" series (0810) and OriginaLast (OM62), our non-skid non-slip one-part moisture cured polyurethane coatings, including the OM62N series which has been approved for military specification by the US Navy.

2. SafetyPad Mats/SafetyPad Plastic Sheets - two parallel systems of truncated domes. These totally-retrofit systems meet the (ADA) Americans with Disabilities Act standards for detectable warnings for the blind.

3. FireHalt - our unique fire-retardant technology

OriginaLast's full line of FireHalt (fire-retardant products) are all based on the same intumescent technology. The various FireHalt powders incorporate variations of the same ingredients in different ratios, supplemented with an assortment of other chemicals to enhance the results. Each is designed to answer the specific requirements of a particular resin system, and, accordingly, require different compliance tests to validate their effectiveness as a flameretardant compound.

FireHalt PRODUCTS AND APPLICATIONS Our FireHalt technology is basically being used in two ways:

(1) Our full line of ready-to-use FireHalt coatings have the intumescent technology built in and offer ease of application with a minimum of Class A protection. This is customarily achieved with less than a 10mil thickness. In most cases, a greater level of fire protection can be achieved, depending on the thickness of the application, the type of resin system, and the required fire specification. The products in this line include:

(a) FireHalt two-part epoxy for Structural Steel

(b) FireHalt Waterborne two-part epoxy

(c) FireHalt OF/OL for our OriginaLast polyurethane coating

(d) FireHalt Latex - a latex-based coating

(e-1) FireHalt High Performance two-part epoxy

(e-2) FireHalt Superior two-part epoxy

(f) FireHalt Clear two-part epoxy Each one of these coatings serves different applications and have undergone an array of different and independent ASTM fire-retardant tests.

(2) Our FireHalt powder additives are designed for incorporation into other resin systems, which include, but are not limited to:

(a) Different kinds of plastics

(b) Fiberglass

(c) PVC

(d) A variety of nylon products (nylon 66, nylon 48, and others)

(e) A variety of construction materials, including foams

(f) Paints and coatings produced by other manufacturers Although our powder additives incorporate the same technology as our epoxy coatings, some modifications have been made to the formulation to produce four different varieties: CAB-2, CAB-3, CAB-3-MW, and OF-OL. These four types can be used independently, or in a blend, depending on the resin system it is to go into and the nature of the fire protection sought. Quite often, we recommend the incorporation of additional chemicals or materials in order to enhance the final performance of the compound.

FireHalt ADVANTAGES While intumescent technology has been well established since the 1950's, our chemists have greatly improved the technology, enabling widespread use of the technology in varying materials. Our FireHalt technology has clear advantages over other intumescent techologies:

(1) Our coatings require a very thin layer, in most cases, to achieve the same results that other systems can only achieve with a much thicker application. (2) The intumescent system is characterized by the creation of a char foam once the substrate is exposed to a high temperature. Our FireHalt coatings are formulated to form thick, dense chars to prevent flame spread and to insulate from heat. However, when the FireHalt powder is being incorporated into other resin systems, the degree of char will vary depending on the materials used.

(3) Unlike many other fire-retardant technologies, FireHalt technology is non-toxic. When it is incorporated in or applied to intrinsically toxic materials, it can help reduce the amount of toxicity inherent in the resulting smoke. This is an especially important factor to consider, as statistics show that most of the fatalities caused by fire are the result of the inhalation of toxic fumes.

Atkins General Construction would like to assure you that we will work with you and our chemists very closely, and spare no effort, in order to meet the fire retardant requirements of your projects. With our variety of FireHalt coatings, we feel confident we can satisfy your fire-retardant coating requirements. Should you choose to incorporate our additives into your own resin systems, our technical staff will be available for consultation and follow-up technical support, as we work together to find the perfect synergy of our technologies.

1. OriginaLast "Original" series (0810) and OriginaLast (OM62), our non-skid non-slip one-part moisture cured polyurethane coatings, including the OM62N series which has been approved for military specification by the US Navy.

2. SafetyPad Mats/SafetyPad Plastic Sheets - two parallel systems of truncated domes. These totally-retrofit systems meet the (ADA) Americans with Disabilities Act standards for detectable warnings for the blind.

3. FireHalt - our unique fire-retardant technology

OriginaLast's full line of FireHalt (fire-retardant products) are all based on the same intumescent technology. The various FireHalt powders incorporate variations of the same ingredients in different ratios, supplemented with an assortment of other chemicals to enhance the results. Each is designed to answer the specific requirements of a particular resin system, and, accordingly, require different compliance tests to validate their effectiveness as a flameretardant compound.

FireHalt PRODUCTS AND APPLICATIONS Our FireHalt technology is basically being used in two ways:

(1) Our full line of ready-to-use FireHalt coatings have the intumescent technology built in and offer ease of application with a minimum of Class A protection. This is customarily achieved with less than a 10mil thickness. In most cases, a greater level of fire protection can be achieved, depending on the thickness of the application, the type of resin system, and the required fire specification. The products in this line include:

(a) FireHalt two-part epoxy for Structural Steel

(b) FireHalt Waterborne two-part epoxy

(c) FireHalt OF/OL for our OriginaLast polyurethane coating

(d) FireHalt Latex - a latex-based coating

(e-1) FireHalt High Performance two-part epoxy

(e-2) FireHalt Superior two-part epoxy

(f) FireHalt Clear two-part epoxy Each one of these coatings serves different applications and have undergone an array of different and independent ASTM fire-retardant tests.

(2) Our FireHalt powder additives are designed for incorporation into other resin systems, which include, but are not limited to:

(a) Different kinds of plastics

(b) Fiberglass

(c) PVC

(d) A variety of nylon products (nylon 66, nylon 48, and others)

(e) A variety of construction materials, including foams

(f) Paints and coatings produced by other manufacturers Although our powder additives incorporate the same technology as our epoxy coatings, some modifications have been made to the formulation to produce four different varieties: CAB-2, CAB-3, CAB-3-MW, and OF-OL. These four types can be used independently, or in a blend, depending on the resin system it is to go into and the nature of the fire protection sought. Quite often, we recommend the incorporation of additional chemicals or materials in order to enhance the final performance of the compound.

FireHalt ADVANTAGES While intumescent technology has been well established since the 1950's, our chemists have greatly improved the technology, enabling widespread use of the technology in varying materials. Our FireHalt technology has clear advantages over other intumescent techologies:

(1) Our coatings require a very thin layer, in most cases, to achieve the same results that other systems can only achieve with a much thicker application. (2) The intumescent system is characterized by the creation of a char foam once the substrate is exposed to a high temperature. Our FireHalt coatings are formulated to form thick, dense chars to prevent flame spread and to insulate from heat. However, when the FireHalt powder is being incorporated into other resin systems, the degree of char will vary depending on the materials used.

(3) Unlike many other fire-retardant technologies, FireHalt technology is non-toxic. When it is incorporated in or applied to intrinsically toxic materials, it can help reduce the amount of toxicity inherent in the resulting smoke. This is an especially important factor to consider, as statistics show that most of the fatalities caused by fire are the result of the inhalation of toxic fumes.

Atkins General Construction would like to assure you that we will work with you and our chemists very closely, and spare no effort, in order to meet the fire retardant requirements of your projects. With our variety of FireHalt coatings, we feel confident we can satisfy your fire-retardant coating requirements. Should you choose to incorporate our additives into your own resin systems, our technical staff will be available for consultation and follow-up technical support, as we work together to find the perfect synergy of our technologies.